NTS®-PU-M: Emergency Disconnect Safety System for Marine Applications

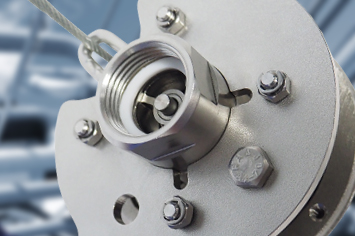

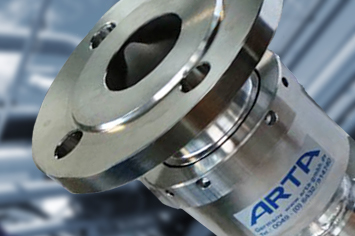

The NTS®-PU-M is a Marine Breakaway Coupling, also known as a Marine Breakaway Coupler or Emergency Release Coupler. Developed by our company especially for harsh marine conditions, its robustness and vigorous resistance to saltwater corrosion makes it the ideal breakaway coupling for offshore applications. The NTS®-PU-M ensures non-destructive, safe separation in hazardous situations, also allowing for rapid and easy reassembly.

The NTS®-PU-M is a Marine Breakaway Coupling, also known as a Marine Breakaway Coupler or Emergency Release Coupler. Developed by our company especially for harsh marine conditions, its robustness and vigorous resistance to saltwater corrosion makes it the ideal breakaway coupling for offshore applications. The NTS®-PU-M ensures non-destructive, safe separation in hazardous situations, also allowing for rapid and easy reassembly.

Due to an unintentional impact on the line, hazardous situations in refueling operations often come about. This happens for a variety of reasons, such as critical weather conditions and rough seas. For this reason, it is advisable to provide the line with an ARTA emergency disconnect safety system suitable for marine applications.

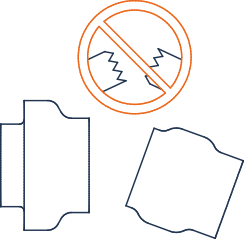

Should an inadvertent tensile force impact the line where the NTS®-PU-M is installed, its two coupling halves will come apart in a controlled manner and their valves immediately close on both sides. No spillage of potentially dangerous media will occur and the safety of the user will be ensured.

Should an inadvertent tensile force impact the line where the NTS®-PU-M is installed, its two coupling halves will come apart in a controlled manner and their valves immediately close on both sides. No spillage of potentially dangerous media will occur and the safety of the user will be ensured.

Protecting the environment due to non-destructive separation

The design of the NTS®-PU-M offers secure, direct separation. The coupling components remain intact, which ensures a lengthy service life for the NTS. Furthermore, the separation mechanism allows the spill-free retention of the media in both coupling halves, so the environment is not impacted and there are no additional material costs.

Quick and easy reassembly on site

Because separation is non-destructive, the Breakaway Coupling may be reassembled easily. The separated coupling halves are reunited using a simple device, and no special tools or spare parts are required, which greatly reduces downtime.

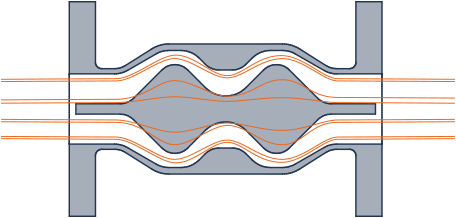

Maximum flow

We designed the flow-optimized NTS®-PU-M by employing the finite element method (FEM), and then following up with flow tests. The results provide a greatly reduced pressure loss, even when the breakaway coupling is at maximum delivery flow.

Patented trigger mechanism with flexible 90° range of activation

The optimized release mechanism prohibits tensile force between a vehicle, the NTS and the rest of the system, so that, even under poor conditions, safe separation is ensured. Due to the 90° range of activation of the separating mechanism, triggering is largely unaffected by the direction from which a tensile force impacts the system.

Fully verified by international certification entities

The NTS®-PU-M is a globally approved safety coupling certified by recognized international entities. There are no safety reservations for its application.

The NTS®-PU-M is used on suction and discharge lines for liquid, gaseous or solid substances. Its use is equally viable on hose lines and pipe loading systems. Its enormous load capacity and available sizes make it the ideal breakaway coupling for the entire marine sector, including ship-to-shore and ship-to-ship loading.

Liquids

Gases

The most important technical data at a glance

| Sizes: | DN150 (6“) bis DN400 (16“) |

| Pressure rating: | PN16 (232psi) |

| Temperature range: | -55°C (-67°F) bis +200°C (+392°F) |

| Body material: | Edelstahl 1.4301/1.4404/1.4571 |

| Sealing: | Elastomere, Perflourelastomere weitere auf Anfrage |

| Connections: | Flansch: DIN/EN, ANSI, ISO, ASME weitere auf Anfrage |

| Conformities: | 2014/68/EU Druckgeräterichtlinie, 2014/34/EU ATEX, EN14432 |

NTS®-PU-M: Emergency Disconnect Safety System for Marine Applications